PriceFree

Aerospace Fasteners

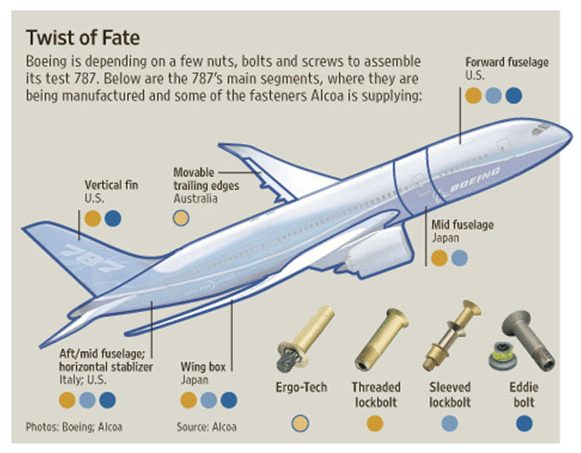

- On average, for example, 2.4 million (2,400,000) fasteners are used to assemble a Boeing 787 aircraft

- 22% are structural bolts (mostly titanium) and the rest is rivets

- Types of Fasteners in Aerospace Industry and their Distinguishing Features:

- Aerospace Bolts

- Aerospace Nuts & Washers

- Aerospace Rivet

Section 1Aerospace Bolts

Lecture 1MaterialsFree Preview

- Bolts are used in aircraft construction in areas where high strength is needed

- Where this strength is not necessary, screws are substituted

- Aircraft quality bolts are made from:

- alloy steel

- stainless or corrosion resistant steel

- aluminum alloys

- titanium

Lecture 2Bolt Head Types MarkingsFree Preview

Bolt Head Types

- There are many head types available, such as hex, slotted, 12-point, spline, socket, Torx, and Phillips.

- Most specifications, including MIL and NAS, DO NOT give a maximum socket head depth. Only the minimum depth is given.

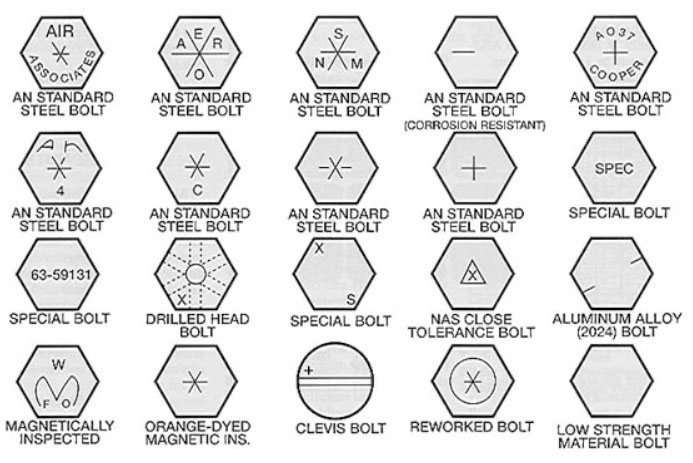

Bolt Markings

- Aircraft bolts will always have a marking on their head

- Do not use bolts without marking on their head because it is probably a commercial grade bolt

- markings vary by manufacturer

Aerospace Structural Bolt Designs

- The most common bolt head styles used in aircraft structures are shown in Figure 3

- The 100° flush head styles, for both the lock bolt type and threaded type, are used for aerodynamic flushness in areas such as skin attachments

Example

-

- What type of bolt is this?

- How do we know by looking at it?

The Answer is..

AN Standard Steel Bolt

Lecture 3Bolt Standardization

Lecture 4Bolt Sizing

Lecture 5Torque

Lecture 6Installation Summary

Lecture 7Structural Bolt Properties

Section 2Aerospace Nuts & Washers

Lecture 8Nuts & Washers

Lecture 9Nuts

Lecture 10More Nuts

Lecture 11Basics of Aircraft Nut InstallationFree Preview

Basics of Aircraft Nut Installation

- When using a castle nut, align with the cotter pin hole

- A fiber nut may be reused if you are unable to tighten by hand.

- At least one thread should be projecting past the fiber on a fiber nut installation.

- No self-locking nuts on moving part installations.

- Do not use AN364 or AN365 fiber nuts in areas of high temperature – above 250′ F.

- Shear nuts are to be used only in shear loads (not tension).

- Plain nuts require a locking device such as a lock washer or a check nut.

- When using a lock washer, place a plain washer between the surface of the airplane part and the lock washer.

- Shear nuts and standard nuts have different torque values.

- Use wing nuts only where hand tightness is adequate.

Castle nut with cotter pin on the nose landing gear of a Piper Tomahawk

Section 3Aerospace Washers

Final Quiz