Let’s Talk EP’s

We are often asked about the differences between the various ethylene-propylene rubber compounds. There are a slew of acronyms used for EP and there are also different cure systems. What are the differences? Well, it is important to know what the differences are because what may work well in one application, may not work well in another.

Let’s start by giving a general overview of ethylene-propylene rubber. EP has excellent ozone, UV, and weather resistance. It also has good mechanical properties. In regards to fluids, EP’s typically have resistance to dilute acids, alkalis, ketones, alcohol, automotive brake fluids, phosphate ester-based hydraulic fluids and water. On the flip side, EP’s will swell considerably in petroleum based fluids.

Ethylene-propylene elastomers can be compounded to operate in continuous service temperatures of

-65°F to +300°F. In steam service the EP can operate at up to 400°F.

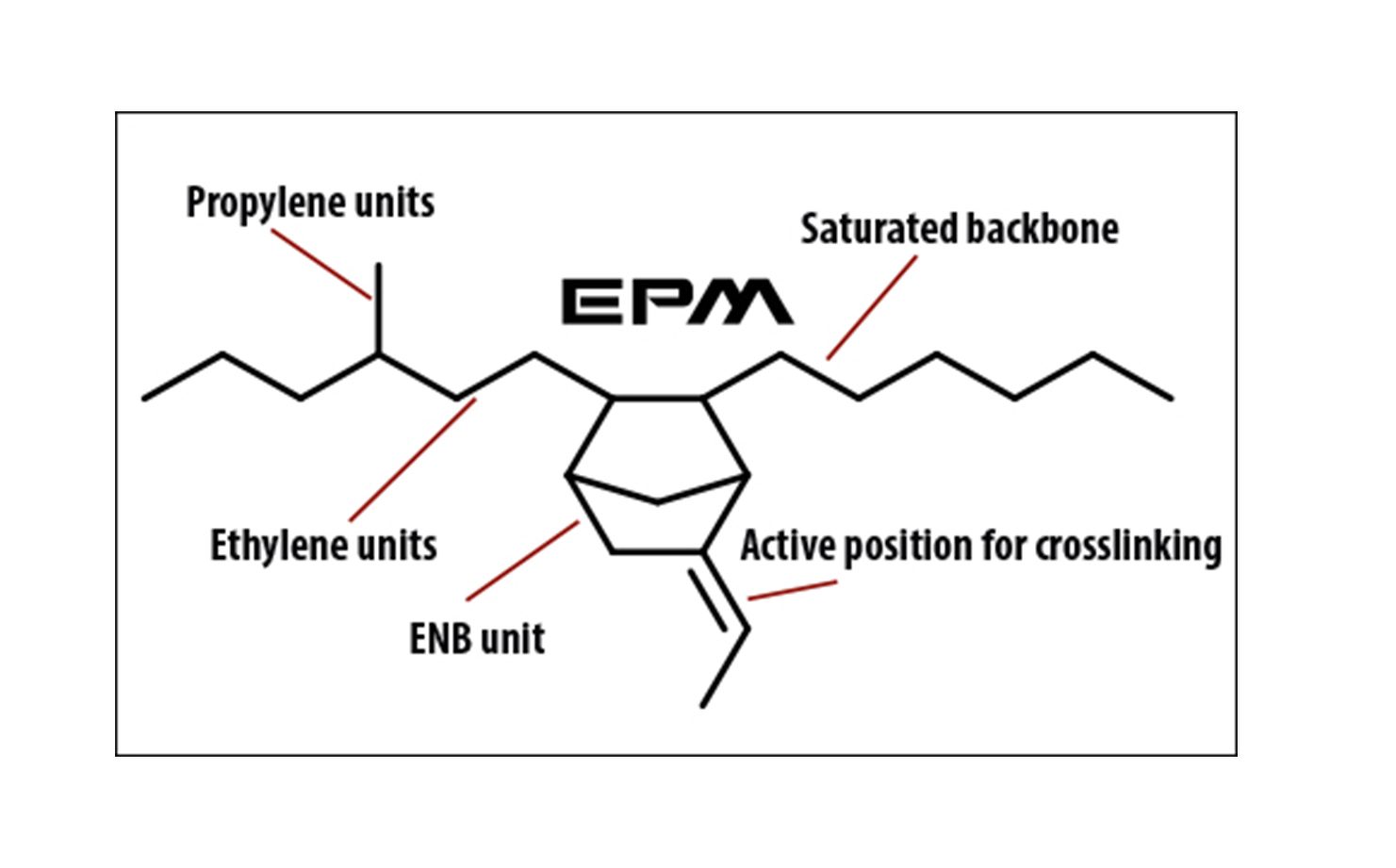

An EP molecule is made up of smaller molecules call monomers. The monomers are linked together to form a chain. The types of monomers used, dictate the type of EP you have.

EPDM

EPDM is the acronym for ethylene-propylene-diene monomer. This type of EP is made up of 3 monomers. When you have 3 monomers it is called a terpolymer, thus EPT stands for ethylene-propylene-terpolymer and is the same thing as EPDM.

EPR

EPR simply stands for ethylene-propylene rubber and can be used to describe the entire family of ethylene-propylene elastomers.